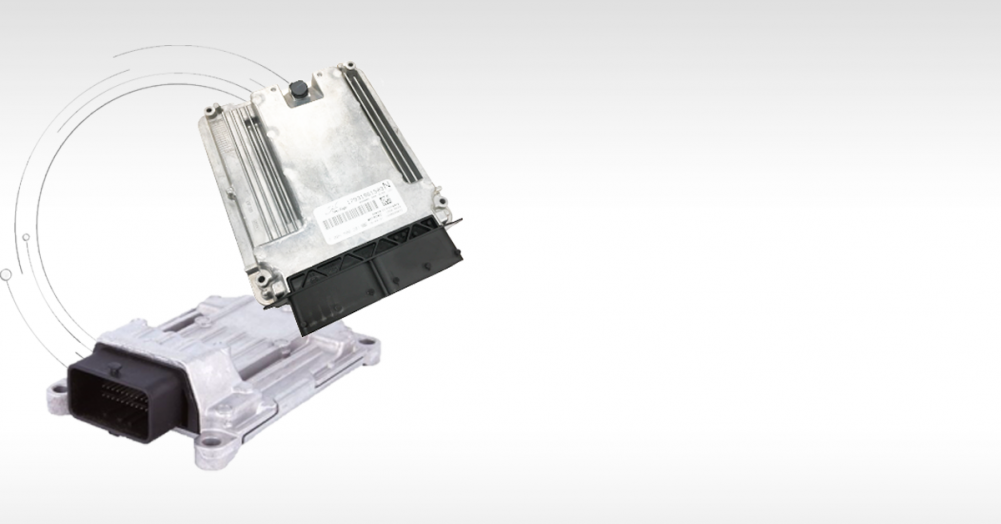

A turbine engine manufacturing company needed to update its obsolete and outdated hardware. It soon realized that it would need to rewrite its legacy control software so it could be applied on a new, reliable, automotive-grade controller. New Eagle was contacted to assist with the process.

Improving Systems, Meeting Specifications

To solve this complex control problem, New Eagle’s team reverse-engineered the manufacturer’s old system into function specifications. Next, it converted these function specifications into software using embedded model-based development (eMBD) tools. New Eagle’s team then focused on improving the electrical system by redesigning the interface with all new components.

Heating Up Production

When it came time to test the system, New Eagle designed a testing plan that verified that the new system would include all the required functions.

Leveraging its eMBD tools, New Eagle developed a running, tested engine to the manufacturer within two months. This new control system allowed the manufacturer to increase production, decrease build time, and deliver a higher quality product, helping the manufacturer cut costs.

Supplying Hardware and Support

New Eagle then worked with the manufacturer’s engineering team, providing training and support so that the team would have the skills and tools needed to continue developing. With New Eagle’s hardware supply chain, the manufacturer could also access the reliable components needed to meet its goals and production schedule.