DEVELOPMENT ENGINEERING SERVICES

Experienced

Production Partner

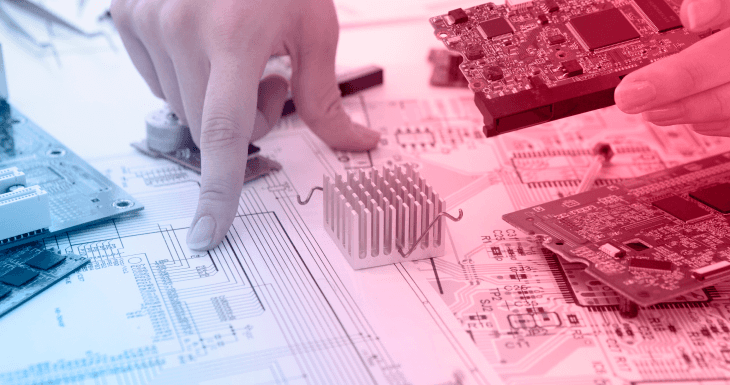

If you're bringing a new vehicle to production, you need expertise across a range of domains:

Our experts plug into your team to fill gaps and provide the big-picture thinking needed to solve complex vehicle control problems. Together, we'll bring your program to market.

End-to-End Support For The Vehicle Development Process

We're the fast, efficient, and reliable partner you need to take your idea from concept to market.

Vehicle Development Tools & Solutions

Create scalable, production systems fast with our embedded model-based development tools, ruggedized hardware, and world-class engineering support services.

Feasibility Consultation

Consult with our team of industry experts during your project’s earliest stage, and get the insight you need to determine its feasibility and next steps.

Control System Design

Using validated, production hardware, and fast, embedded model-based design software tools, our team can create a custom control system solution that’s right for your machine. If you prefer to oversee this process yourself, you can augment your team with our specialists who will support you as you develop your prototype.

Embedded Controls

Innovative companies ask us to lead them in embedded model-based development (eMBD) for their mechatronic controls. While our Raptor™ software tools make it faster and easier to develop, calibrate and test embedded software, our engineering team can support you, or even lead the development process of your embedded system for you as a full-service solution.

Control System Integration

Our engineering team integrates your control system into your machine's prototype and documents each step along the way so you can easily and safely transition to production.

Modeling and Simulation

Using state-of-the-art software tools and years of experience, our team can help you model, simulate, and test different conditions to ensure your machine meets production requirements.

Hardware Supply Chain Management

New Eagle’s strategic partnerships with market-leading hardware manufacturers give you access to validated hardware from your machine’s low-volume prototype phase through high-volume production. Let us manage your supply chain, so you can place one easy order.

Meeting ISO/ASIL Safety Requirements

Part of your vehicle development strategy is addressing the safety requirements your machine must meet to move into production. Scrambling to meet these requirements can keep your vehicle stuck in development with expensive rework.

Our Certified Functional Safety Engineers can design a production control system to get your vehicle on the road safely and quickly. We can assess systems and develop functional safety concepts to meet Automotive Safety Integrity Level (ASIL) and ISO 26262 requirements.