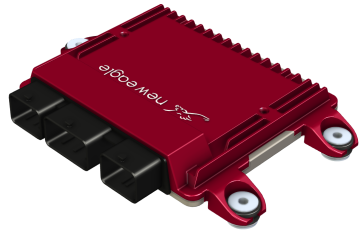

Production-Ready, Customizable Electronic Control Units (ECUs)

Our ECUs Are

BUILT FOR

Our Most Popular ECUs

Find the Right ECU for your project

Micro

Memory

Inputs

Outputs

Communication

Requirements

Frequently Asked Questions

Does New Eagle have a customer support team?

Yes, our customer support team is available to assist you Monday through Friday, 9 am to 5 pm EST. We also offer premium support packages.

How do I order New Eagle ECUs?

Through the New Eagle Store or by contacting a New Eagle Sales Representative.

What language is used to program Raptor ECUs?

We utilize our Raptor suite of software tools which uses model-based design in Simulink.

What level of validation do New Eagle's ECUs have?

New eagle's ECUs are environmentally tested and automotive-grade. Each ECU has environmental ratings specific to its design.

What is the typical lead time for New Eagle's Raptor ECU line?

Prototype quantities (1 - 20) are in stock and ready to ship for most ECUs. Production-level quantities are available with a volume estimate.

Can New Eagle help me program my ECU?

Yes, New Eagle has several services that can offer assistance, including in-person or virtual Raptor training that covers the basics of programming with Raptor-Dev.

While our Raptor software tools make it faster and easier to develop, calibrate, and test embedded software - our engineering team is also available to support you. They can even lead the development process of your embedded system as a full-service solution.

Can New Eagle help me design and spec my system?

Yes! Through an engineering Phase 1 project, New Eagle engineers can help your team create your system architecture and bill of materials. In a Phase 2 project, our team will design your system, procure necessary components, perform system integration, and validate the concept with a prototype model.

Are Raptor ECUs ISO 26262 capable?

New Eagle offers several ECU options for projects that require ISO 26262, including the RCM112 and RCM80. In addition to ISO 26262 capable ECUs, New Eagle's certified engineering consultants can assess systems and develop functional safety concepts to help you meet ASIL ratings and ISO 26262 requirements.