The EV market has expanded well beyond little coupes and sporty sedans. In fact, off-highway mobile equipment — like compact construction and turf care vehicles — is also rapidly going digital and electric. That growing market is pushing for better system design and more efficient energy management.

Let’s look at what the market is demanding from developers and how New Eagle’s Raptor Platform can help you meet those market demands.

Mobile Market Motivation and Demands

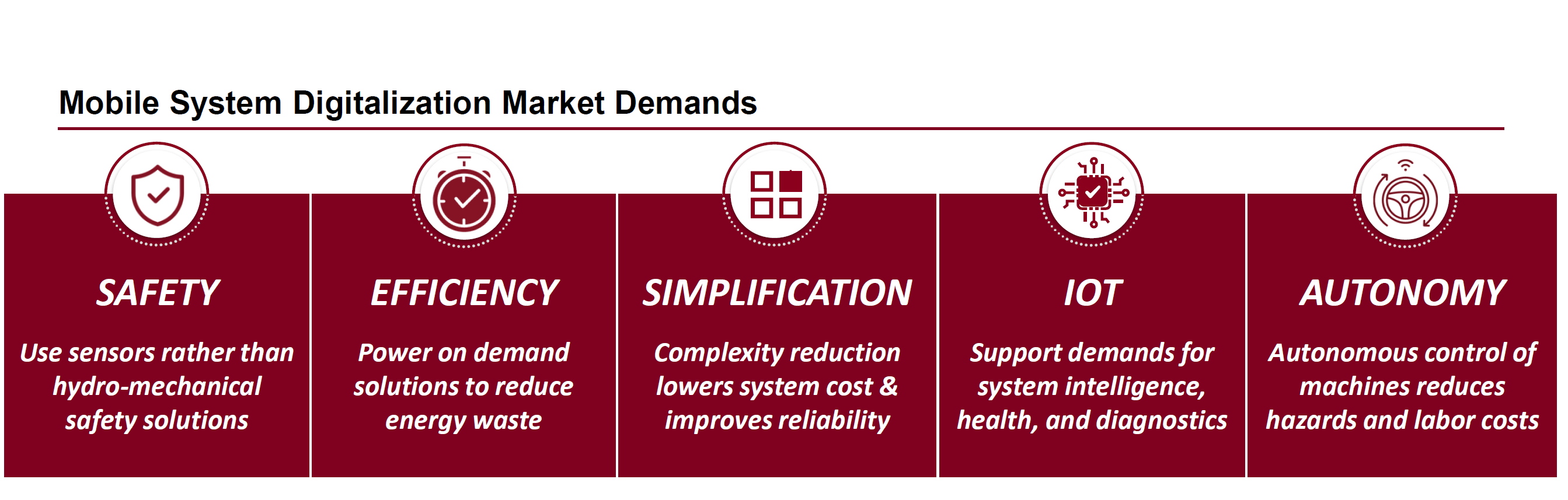

The market wants digitalization. But how and why we’re going digital is complex. So, we’ll break these market demands down into five specific categories to make things a bit more clear.

Safety

Safety first, right? For off-highway digitalization, this typically entails replacing hydro-mechanical safety solutions with sensors. These sensors can detect the tiniest changes in their environment with greater sensitivity and accuracy.

Efficiency

With power-on-demand solutions, digitization streamlines the flow of energy to keep waste down. In addition to lowering costs, this makes it easier to comply with green city initiatives and solutions.

Simplification

Market demands like autonomy, IoT, and electrification are increasing the complexity of mobile machines. But keeping things simple has a number of advantages; it lowers a system’s overall cost and makes it more reliable. So it’s not surprising that OEMs are clamoring for simplicity. One way to simplify control systems is by replacing classic hydromechanical systems with electronic solutions. This can replace costly component complexity with software and increase performance.

IoT

The Internet of Things, or IoT, has a mesh of connected devices. These objects have sensors, processors, and software that enable data exchange, analytics, and remote control. With off-highway vehicles and equipment, this boils down to a demand for increased system intelligence and diagnostics to keep that system healthy.

Autonomy

While equipment with self-driving and self-operating capabilities makes some people nervous, autonomy actually reduces hazards by taking human error out of the equation – if risks are adequately managed. With the autonomy that digitalization can offer, companies can cut down on field labor costs and reinvest their people and money in other areas.

How New Eagle Supports Digitalization

We offer total system management solutions with our Raptor tools and products, so you can build a complete production-level system from I/O, including telematics functionality, to controllers and displays. By focusing on hydraulic, powertrain, and auxiliary efficiency, we can reduce losses in and optimize these systems. With Raptor, you can expect a major reduction in both your development costs and time to market – without sacrificing the standards you expect from high-volume production.

With New Eagle, you can feel confident from prototyping through production and into field service for your off-highway vehicles and equipment.

Up Next: Electrification

In the second part of our installment on off-highway vehicles and equipment, we’ll tackle how the market demands differ for electrification and how New Eagle can electrify your process and off-highway EV projects.