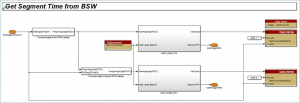

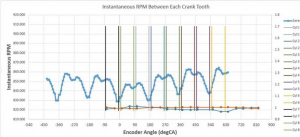

To design and calibrate OBD monitors, especially misfire, expensive and complicated development ECU hardware is typically used to collect data quickly enough to analyze each individual firing event, like the picture below.

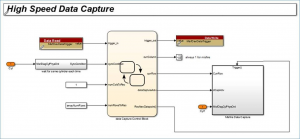

This expensive development hardware is no longer a requirement thanks to Raptor and the ECM196, according to New Eagle Engineer, George Kelly. In Raptor, he set up a trigger to capture and store faster data in the ECU that would not be available over the slower CAN XCP link. Basically, all one has to do is trigger it once and it fills arrays in the ECU memory at a high speed, then you can read out those arrays more slowly over CAN XCP later.

Two pictures below are parts of the misfire detection using Raptor ECM196. Raptor is an Embedded Model-Based Development (eMBD) development tool for rapid development of production control systems. The ECM196 is an open automotive controller programmed with Raptor and exclusively available from New Eagle and its network partners.