Construction, drilling, and turf-care machines like tractors, mowers, drills, and excavators are all going electric. And like any other vehicle, off-highway mobile equipment designers are working hard to improve system design and energy management.

In this post, we’ll share what the market demands are for electrifying these types of vehicles and how New Eagle can support that effort.

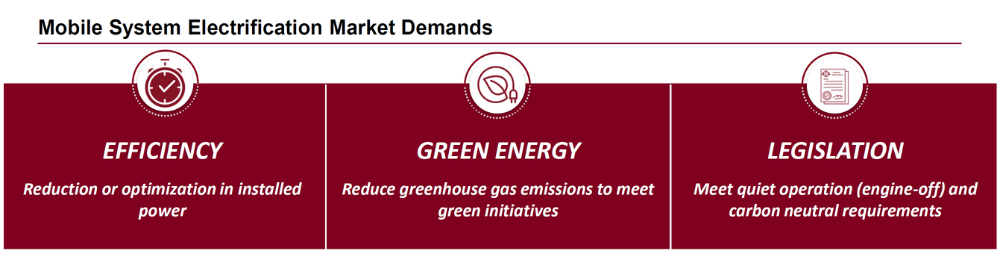

Mobile Equipment Market Demands

One of the market demands for electrification of off-highway equipment – efficiency – was also covered in our previous post on digitalization. But there’s also a high demand for electrification coming from green energy initiatives, in part through enacted legislation. Let’s take a closer look.

Efficiency

When improving electrification efficiency, developers are less concerned with reducing waste throughout the process than they are with the power source itself. To increase efficiency, they will examine how to reduce installed power sources — or optimize them. Efficiency also means improving diagnostics and long-term functionality to reduce maintenance downtime and increase lifespan.

Green Energy

More and more people, governments, and companies are seeking ways to lessen their impact on the environment — and encouraging others to do the same. With electrification, mobile equipment can use renewable energy to reduce greenhouse gas emissions.

Legislation

The green energy movement has encouraged a variety of legislative solutions to reduce emissions and ameliorate environmental impact. For instance, vehicles need to meet new quiet operation standards defined by local governments, such as California’s Noise Element Guidelines. Additionally, governments are creating new requirements meant to reduce greenhouse gas emissions, such as the California Air Resouce Board (CARB). Read how New Eagle helped Kolberg-Pioneer Build an electric hybrid rock crusher to meet CARB’s new standards in this case study.

How New Eagle Supports Off-highway Equipment Electrification

New Eagle is well versed in a variety of EV solutions, as well as staying ahead of the game on industry standards and legislative requirements.

New Eagle’s Raptor Platform

Our Raptor production-ready platform is designed to accelerate your development timeline while minimizing your cost and risk. Our tools cover control system development, calibration, advanced testing, remote diagnostics, and service. We’re with you from prototyping to production to field service.

On average, Raptor shaves 9 months off the typical timeline from development to production of an electrification platform.

You get flexible hardware options, whether you’re looking for something as simple as off-the-shelf or as complex as bring-your-own. With flexible scaling, you can design a solution for a single user or an enterprise-level team. Plus, open architecture means your company can internalize controls development and implementation.

Your One-Stop Shop for Digitalization and Electrification

Performance, flexibility, and speed make up New Eagle’s core philosophy. We’ve created over 100 unique systems for equipment and vehicles of all different sizes — from a couple hundred pounds to tens of tons. Think of us as your engineering extension so you can get concepts developed fast and moving to market while meeting the changing demands of your markets.

Ready to digitalize and electrify? Reach out to our sales team today.